Plastic Optical Fiber - POF

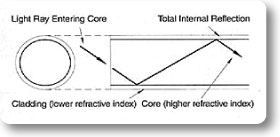

A typical plastic optical fiber ("POF") consists of an inner acrylic plastic core coated with a thin cladding of fluorinated polymer. Since the refractive index of the outer cladding is lower than the core, light entering one end of a fiber reflects along the interior core material at the interface of the core and cladding. Light passes through the length of the fiber in a zigzag path on its way to the other end. Plastic optical fibers have advantages over glass optical fibers in cost, weight, durability, and flexibility, that permitted their use in several applications.

Some trials to integrate POF in textiles structure were realized by Pangaia Grado Zero, that manufactured a garment inserting the POF, together with textile fibers, into the weaving structure. The result was a jacket, Luciferas, having a red luminescent effect on the sleeves but with several problems of rigidity, breathability and comfort on the skin, that incited PGZ into continuing its studies on new luminescent devices applicable to textile sector.

Electroluminescent film

Electroluminescent film is a device in which a layer of light emitting phosphor is printed between two very thin electrodes, one is opaque and the other is transparent. When alternating current is applied, the phosphor rapidly charges and discharges, resulting in the emission of light that could be blue, green, orange or white. Many additional colours can be achieved by adding dyes and filters to the active EL area. Electroluminescent film offers numerous advantages over other lighting sources: low thickness, generating no heat, energy efficient, providing uniform lighting with no dark areas and versatility.

In particular Pangaia Grado Zero's staff thought to integrate these electroluminescent devices into some garments used in sport applications where high visibility is a key point. So here is the motorcycling jacket (LQ Jacket) with an electroluminescent film completely integrated on the back and controlled by a power head inside. This element solve the visibility problem with a flexible and washable system. Another example is the S1 sailing suit that comes from the Transat 6.50 experience and, in the updated version, introduces some innovations in terms of materials and design. An electroluminescent flexible film was in fact applied along the backbone and controlled by a switch inside the pocket, this will permit to increase the visibility in sea also in adverse weather conditions.

Electroluminescent textiles

The next development of the electroluminescent film is the electroluminescent fabric, that is composed, like for the plastic film, by a layer of light emitting phosphor printed between two very thin electrodes and subsequently spread, following some special techniques, on a textile substrate. The obtained device has very interesting properties including a good brightness and durability together with a very high flexibility and versatility. It is possible, in fact, to customize its shape, dimension, colours, graphics effects and, choosing the most suitable textile support and its external coating, to obtain many special properties like flame resistant, waterproofness, washability, stain and abrasion resistance. Thanks to these enchanting peculiarities and to a collaboration with an American company, producer of these electroluminescent fabrics, Pangaia Grado Zero is studying the feasibility to integrate this technology into textile, interior design, automotive, tuning, sport and safe equipment sectors. For further informations please contact the R&D, Technology Transfer and Projects