Shape memory polymers have the capability of changing their shape in response to external stimuli, one of them is temperature. Thermo-responsive shape memory polymers consist of two polymer components and resulting two phases, one with a higher melting temperature than the other.

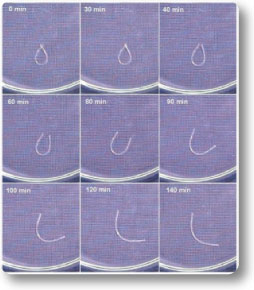

The shape-memory effect is not related to a specific material property of single polymers, but instead is realized from a combination of the polymer structures and their morphologies. The phase responsible for the highest thermal transition, such as highest melting point among all the phases, is the basis for the permanent shape. Above this temperature the polymer is completely in the melt state. While the glass transition temperature of the other phase can be used as a molecular switch for a temporary shape. This material, in fact, after processing into a form, assume a permanent shape which can be deformed to produce other shapes and then, by applying heat, is able to return to its initial shape.

Some of the shape memory polymers are bio-compatible and biodegradable and, currently, their main applications are in the medical field. Potential non-medical applications include carrier systems for cosmetic and beauty care products, optical, electronic and mechanical parts for control systems and special plastics for the repair of accident damage or cars. However, since shape memory polymers are not expensive to produce, their applications could be easily broadened to other areas, e.g., niche textiles, to take advantage of their unique properties.

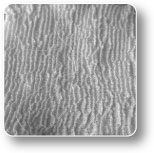

This is, in fact, one of the objectives of Leapfrog project (http://www.leapfrog-eu.org/) that is aiming at a technology breakthrough in the clothing industry. In ambit of this project Pangaia Grado Zero shared its competence in non-conventional textiles in order to solve, together with the other partners, some problems regarding shape memory polymer's synthesis, their extrusion, the physical and mechanical properties of the obtained yarn, its workability in current textile machines, design of the most suitable weaving structure to obtain a well valuable effect and, at the end, it was possible the realization of the first smart orthogonal hybrid fabric made of Shape Memory Polymer.